After using the cyanotype technique on paper, I tried another technique – cyanotype on glass.

Liquid emulsion is applied to glass and washed with water.

The task sounds simple. Is it?

EMULSION PREPARATION FOR CYANOTYPE ON GLASS :

Potassium Ferrocyanide 28g

Ferric Ammonium Citrate 82g

Oxalic acid 3g

Gelatine 80g

Water 600ml

The process begins by mixing 3g of oxalic acid in 600 mL of distilled water, followed by Potassium Ferrocyanide 28g, Ferric Ammonium Citrate 82g, and finally 80g of gelatine. Prepare everything in cold water. The water should be cold for gelatine because the gelatine particles will not stick to the lumps, and it will be easier to dissolve them. We must mix the solution until everything is dissolved. The next step is to heat the pan to 65 degrees Celsius with constant stirring. When the liquid becomes viscous, almost like water, we stop heating it and stirring. This liquid is now prepared to be filtered, which can be done with an ordinary coffee filter. The emulsion is now finished!

After filtration, store the finished emulsion in a dark, light-tight container. Its lifespan is around one year. You can use foil containing the films or photo paper, or if you have none of this, plain aluminium foil to wrap the jar in which the emulsion is stored. It is recommended that the emulsion “stabilize” for a day or two before use. The main difference with the ordinary cyanotype technique is its substrate, which is now glass instead of paper.

Depending on the photo format, 2mm or 3mm thick glass is used. Smoothing the edges of the glass is desirable so that we do not risk injuries when handling it.

Place the jar with the emulsion in hot water (approx. 65 °C) and wait until the emulsion is entirely liquid. Prepare the glass and the spoon that you will use to scoop the hot emulsion. The emulsion is poured into the centre of the glass until it covers approximately 70% of the surface, slowly pouring from edge to edge, and the rest is poured into a separate container. Filter the emulsion residues before returning to the emulsion jar to avoid contamination with possible dust or debris from the glass. The coated glass plate is placed vertically on the blotting paper to allow the emulsion to dry. Excess emulsion accumulates at the bottom edge of the plate, and it is necessary to move the plate several times to remove the excess emulsion. Drying speed depends on the temperature and humidity in the air. Do not dry the glass with a blow dryer or over strong heat sources, as the emulsion will start to melt and will be unusable.

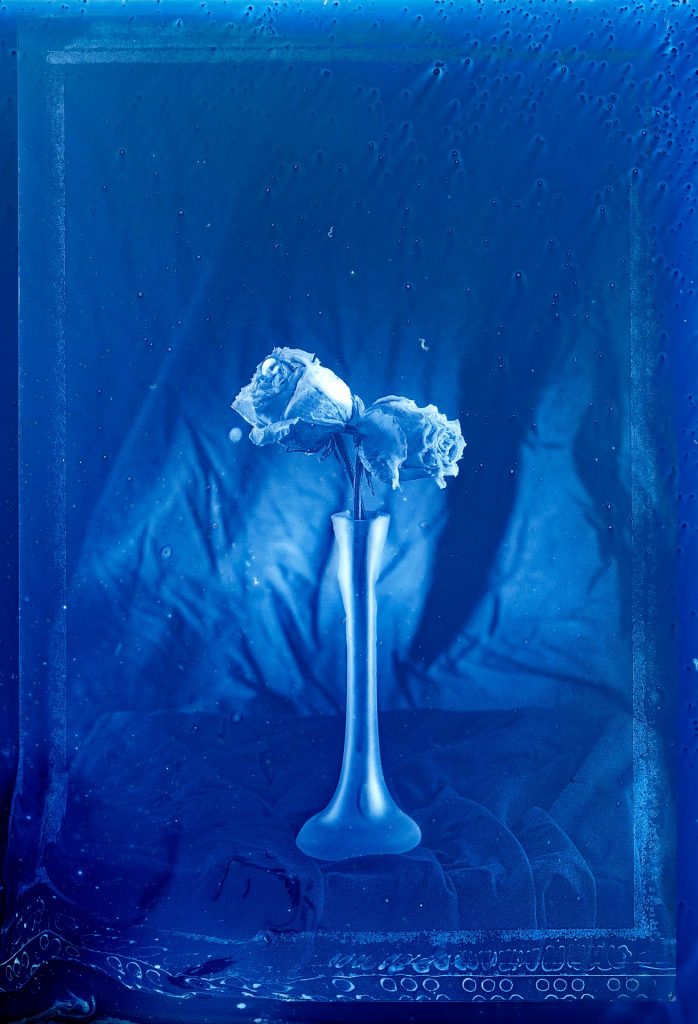

In the gallery you can see some of my works –

cyanotype on glassHere are some pictures from the lab while preparing a cyanotype on glass process.